Post-doctorate

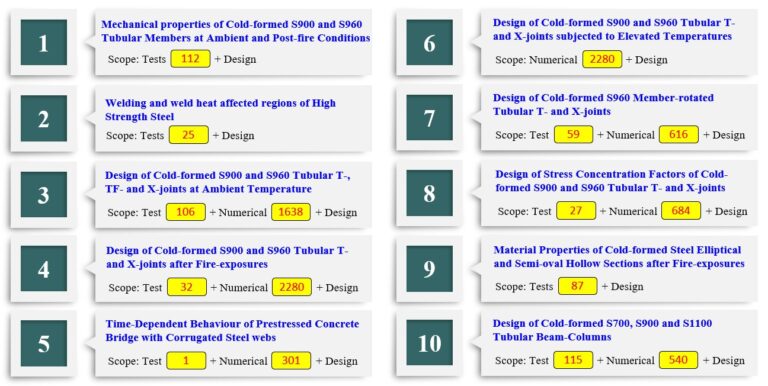

Numerical investigation and design of cold-formed S900 and S960 steels tubular T- and X-joints:

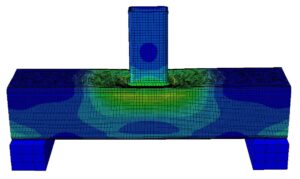

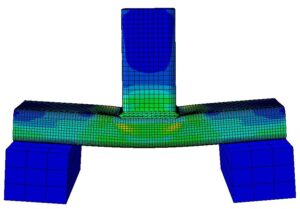

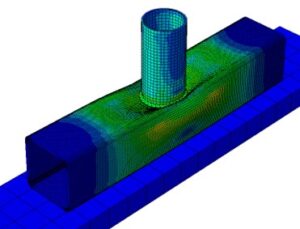

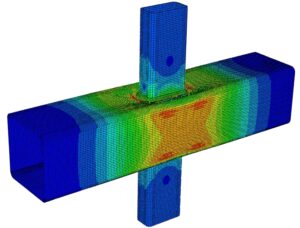

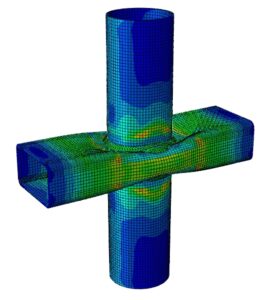

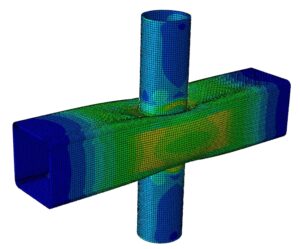

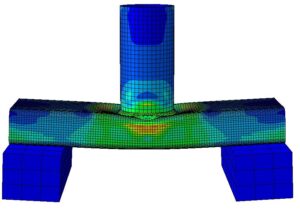

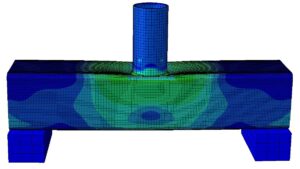

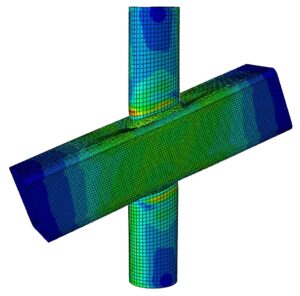

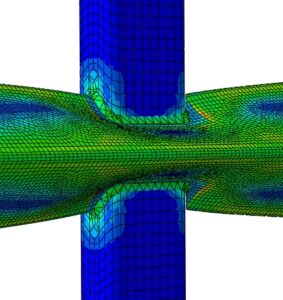

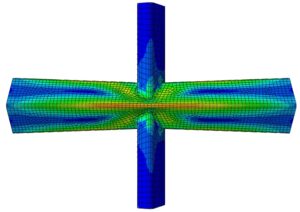

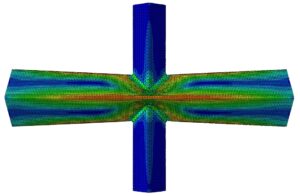

- Traditional (RHS-to-RHS and CHS-to-RHS) T- and X-joints at ambient and elevated temperatures as well as under post-fire conditions. (5112 FE simulations)

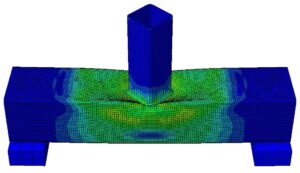

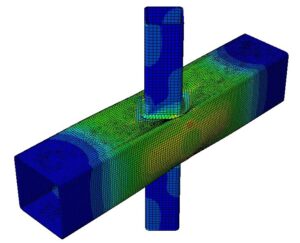

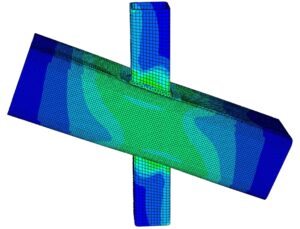

- Traditional (RHS-to-RHS and CHS-to-RHS) non-90° X-joints and fully chord supported T-joints. (1086 FE simulations)

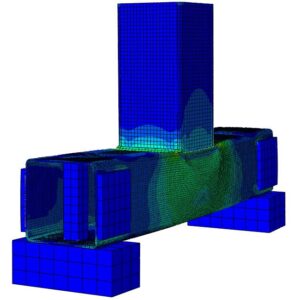

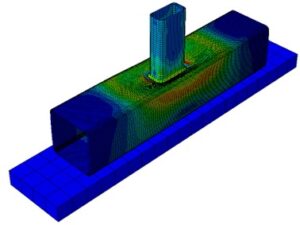

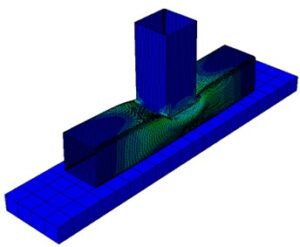

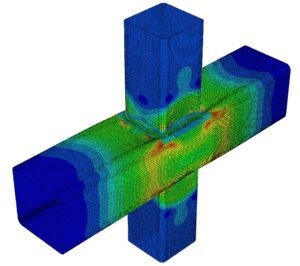

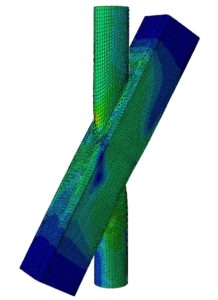

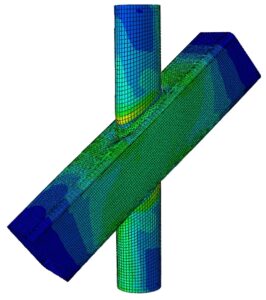

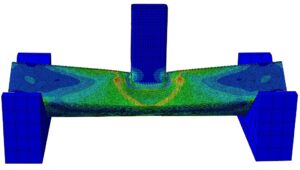

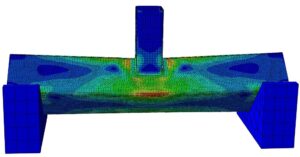

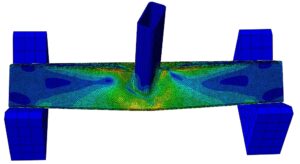

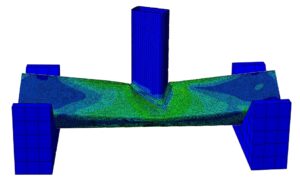

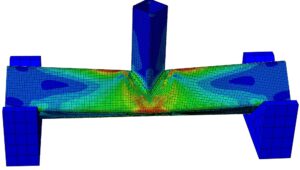

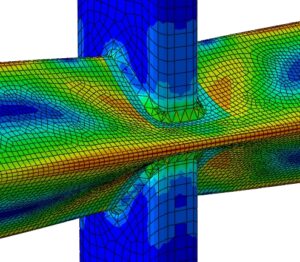

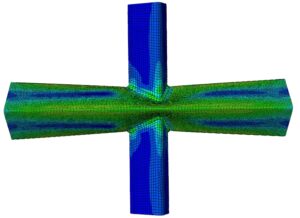

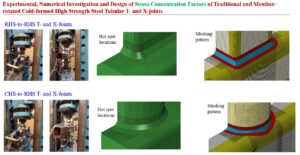

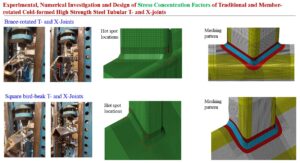

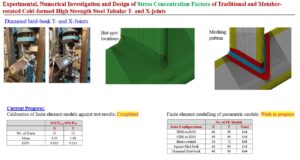

- Member-rotated (brace-rotated, square bird beak and diamond bird-beak) tubular T- and X-joints. (616 FE simulations)

Overall, numerical investigation comprised 6814 finite element (FE) models, which replicated various configurations and types of tubular T- and X-joints under different temperature conditions.

Ph.D.

Experiments to investigate mechanical properties and behaviour of cold-formed S900 and S960 steels tubular T- and X-joints:

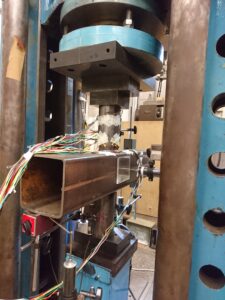

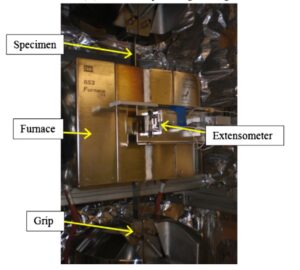

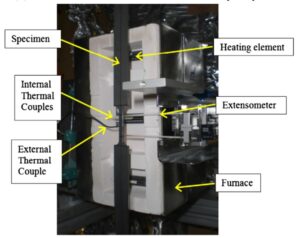

- Mechanical properties of cold-formed S900 and S960 steels tubular members under tension and compression at ambient and post-fire conditions. Mechanical properties of weld heat-affected regions, welding filler material and welding weakest link. (150 tests)

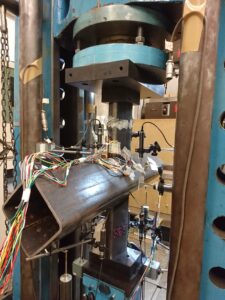

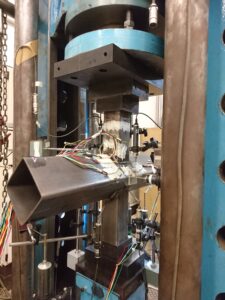

- Static behaviour of traditional T- and X-joints at ambient and post-fire conditions. (90 tests)

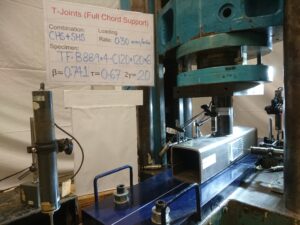

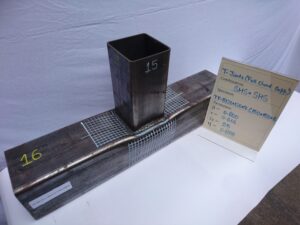

- Static behaviour of traditional non-90° X-joints and fully chord supported T-joints. (48 tests)

- Static behaviour of member-rotated T- and X-joints. (59 tests)

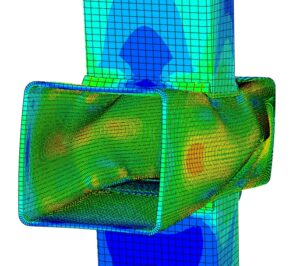

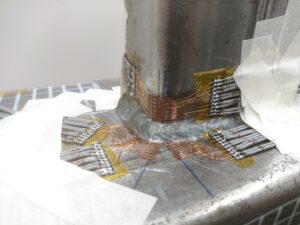

- Stress concentration factors of traditional and member-rotated tubular T- and X-joints. (27 tests)

Overall, experimental investigation comprised of 150 material properties tests and 224 tubular joint tests.

M.Sc. (Eng.)

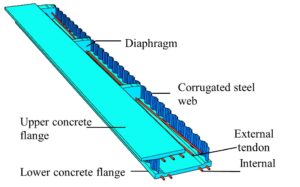

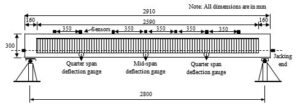

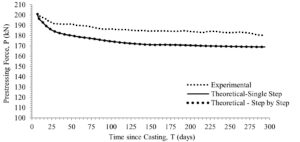

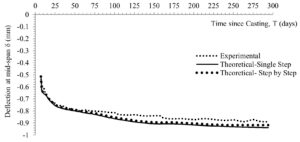

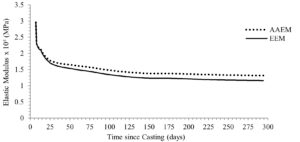

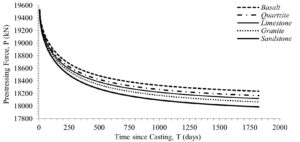

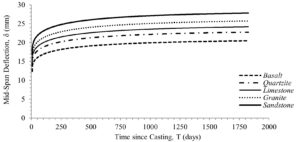

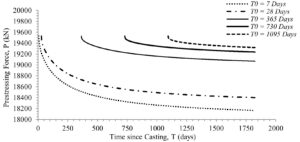

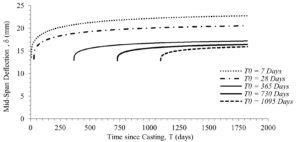

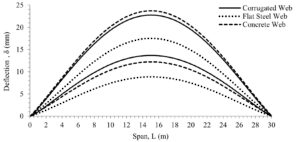

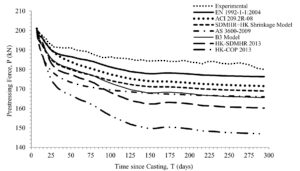

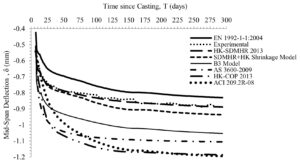

Experimental and numerical investigation of time-dependent behaviour of prestressed concrete bridge with corrugated steel webs. The experimental results were validated through a MATLAB based finite element code followed by a detailed parametric study. (1 test and 301 numerical simulations)

On-going

Stress concentration factors of traditional (RHS-to-RHS and CHS-to-RHS) and member-rotated (brace-rotated, square bird beak and diamond bird-beak) cold-formed S900 and S960 steels tubular T- and X-joints. (684 FE simulations)

Future

Behaviour of high performance steel and composite materials subjected to elevated temperatures and post-fire conditions